Submerged-Arc Welding

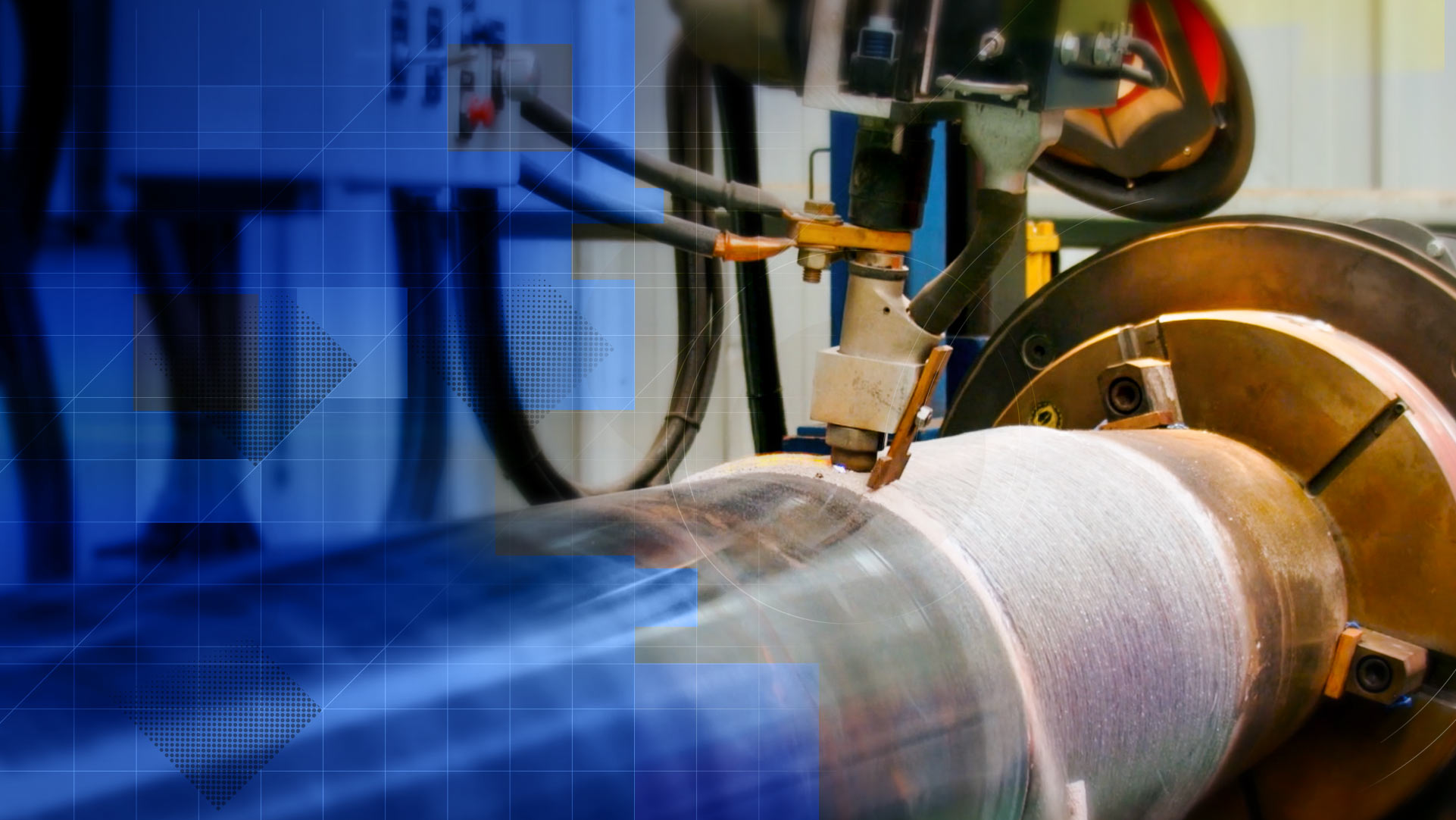

Submerged-Arc Welding (SAW) is a proven, reliable process known for its high quality weld metal deposits and high deposition rates.

SAW is ideally suited to the longitudinal and circumferential welds required for the manufacture of cylinder rods and surfaces. This process is capable of superior joint penetration and optimal deposit efficiency.

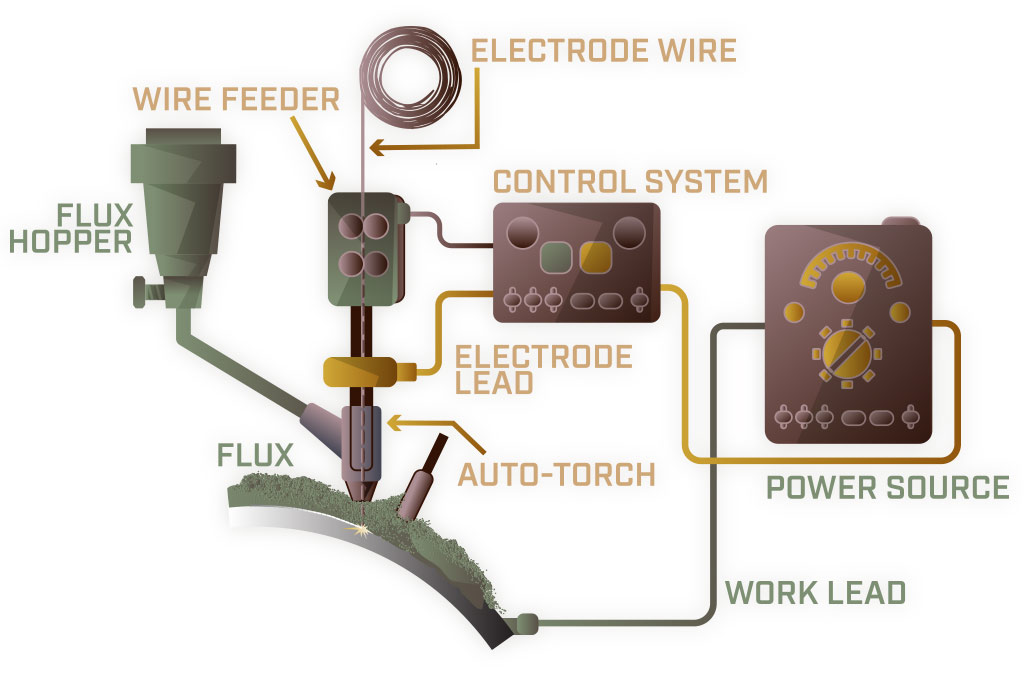

Submerged-Arc Welding Process

Submerged-arc welding (SAW) involves the formation of an arc between a continuously fed electrode and the workpiece. A blanket of powdered flux, which generates a protective gas shield and a slag (and may also be used to add alloying elements to the weld pool), protects the weld zone. A shielding gas is not required. The arc is submerged beneath the flux blanket and is not normally visible during welding. Great reliance is placed on parameter settings and positioning of the filler wire.

![]()

Submerged-Arc Welding allows for the joining of thicker materials and weld metal overlay for dimensional restoration and the application of corrosion resistance/hard surface coatings.