Longwall Shield Repairs

Swanson’s well-qualified technicians refurbish longwall mining equipment that includes:

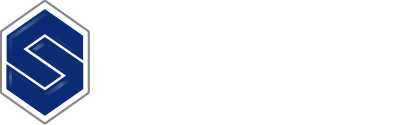

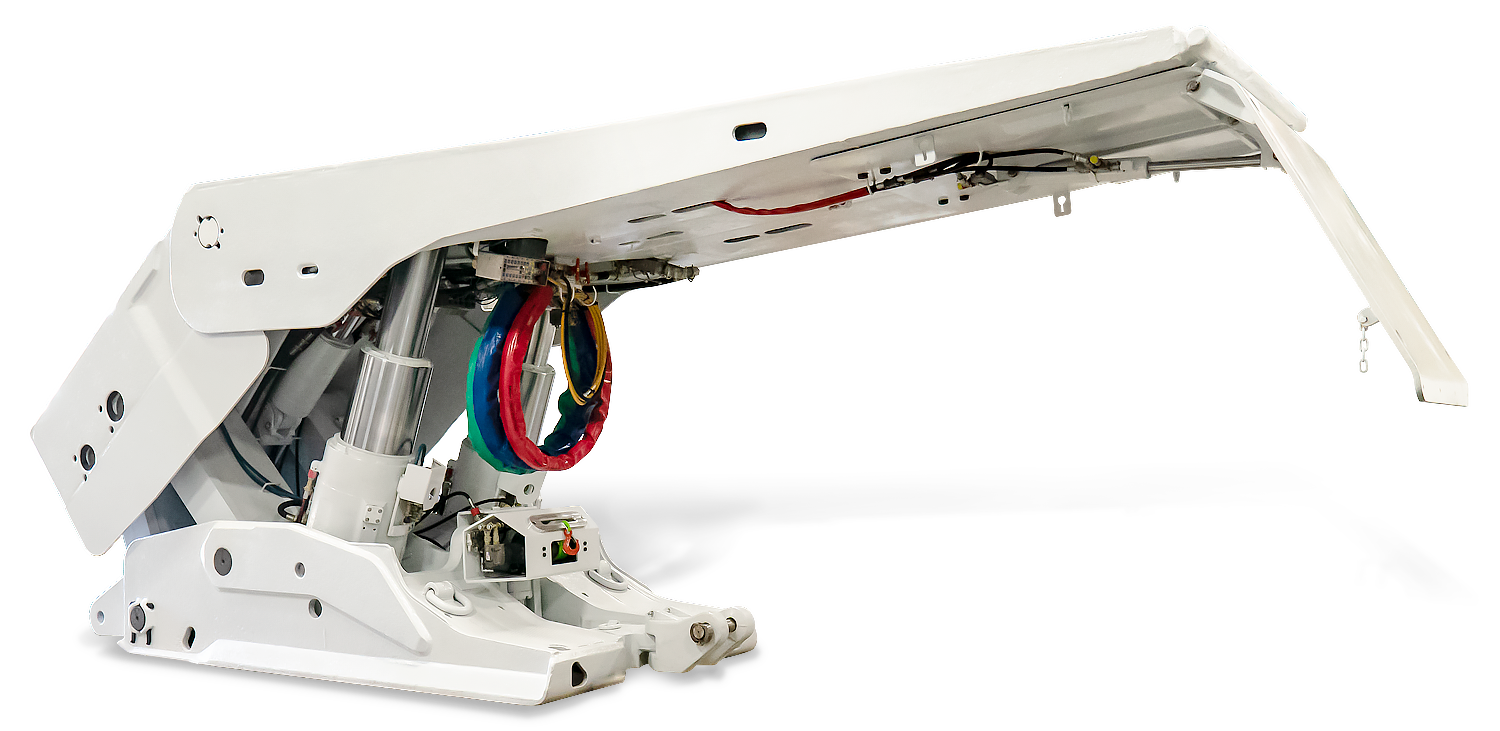

- Complete longwall roof supports

- Repair and/or manufacturer new longwall shield cylinders

- Water spray systems for shield canopies

- Shield canopy extensions

- Specialty winches | Mono-rail products

- Replacement of longwall side shields

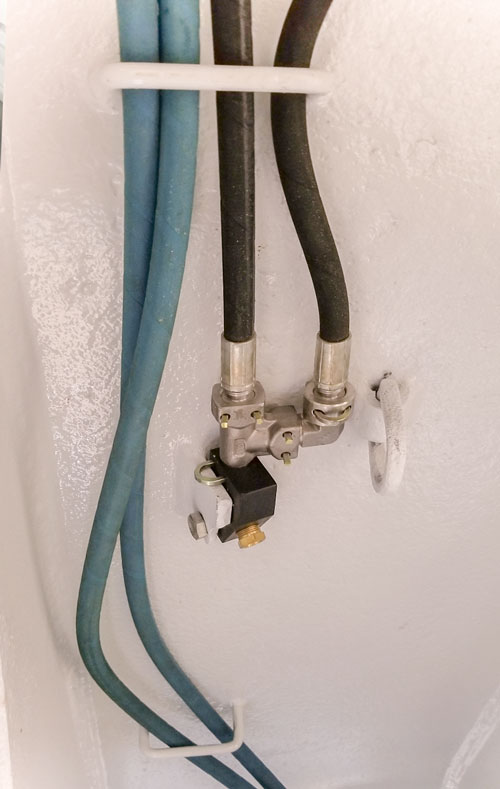

- Cylinders, valves, and electronics

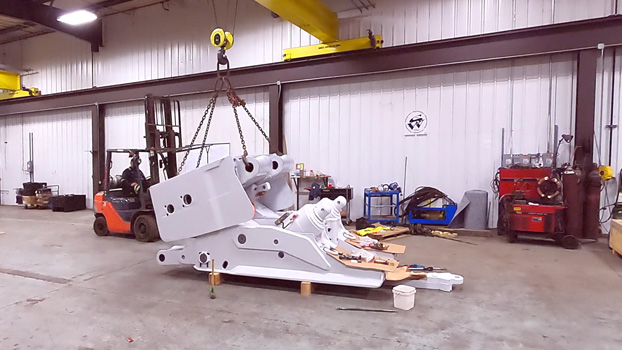

Swanson repaired and rebuilt roof supports have a proven history of reliability and cost effectiveness when compared to new units.

Longwall Shield Repair Process

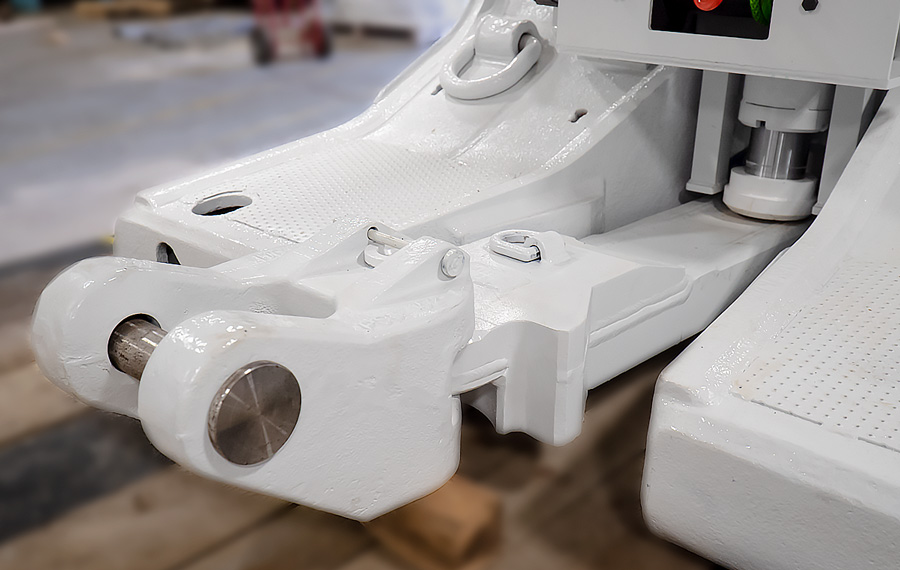

Base Repair:

- Disassemble shields completely

- Clean and sort all components

- Test all attached hydraulic system components to include cylinders, hydraulic and hydraulic check

- Test, record and label attached yield valves

- Function test shield completely with attached electronic system to include sensor reading

- Function test water spray system

Cylinder repair:

- Repair attached hydraulic cylinders to customer specifications, including laser clad plating

Structural repair:

- Sandblast all attached steel components

- Measure and record finding of link pin fits

- Mag Particle testing of high stress area on base, canopy and caving back

- Bore weld and bore link pin fits back to OEM specification

- Provide heavy duty rear links with thicker side walls to address stress area on original links

- Provide heavy duty front links to address stress area on original links

- Inspect and weld repair to the attached ram relay bar system to include remove pin slop in system

- Provide new ram connection pins. Design and supply new tapered rear pin keep

- Provide new heavy-duty top leg keepers

Additional repairs:

- Coordinate the retrofit of new electronic operation system

- Design mounting brackets for all new components supplied

- Mount new electronic system components paying close attention to maintenance friendly locations

- Reconfigure the in-shield hose and fittings placement/routing paying close attention to placement to make the shield maintenance friendly

- Provide and supply new shield hose and fitting overall print

- Add additional options – Flipper, etc.

- Assemble and prepare for shipment

Mine Shield Units Have Been Repaired at Swanson Using Specialized Onsite Equipment That Includes: Large Boring Mills, Burning Tables and Automatic Bore Welders.

Swanson is proficient in fast, efficient remanufacturing and repair of longwall roof supports and sidewall hydraulic supports, as well as underground coal mining equipment.

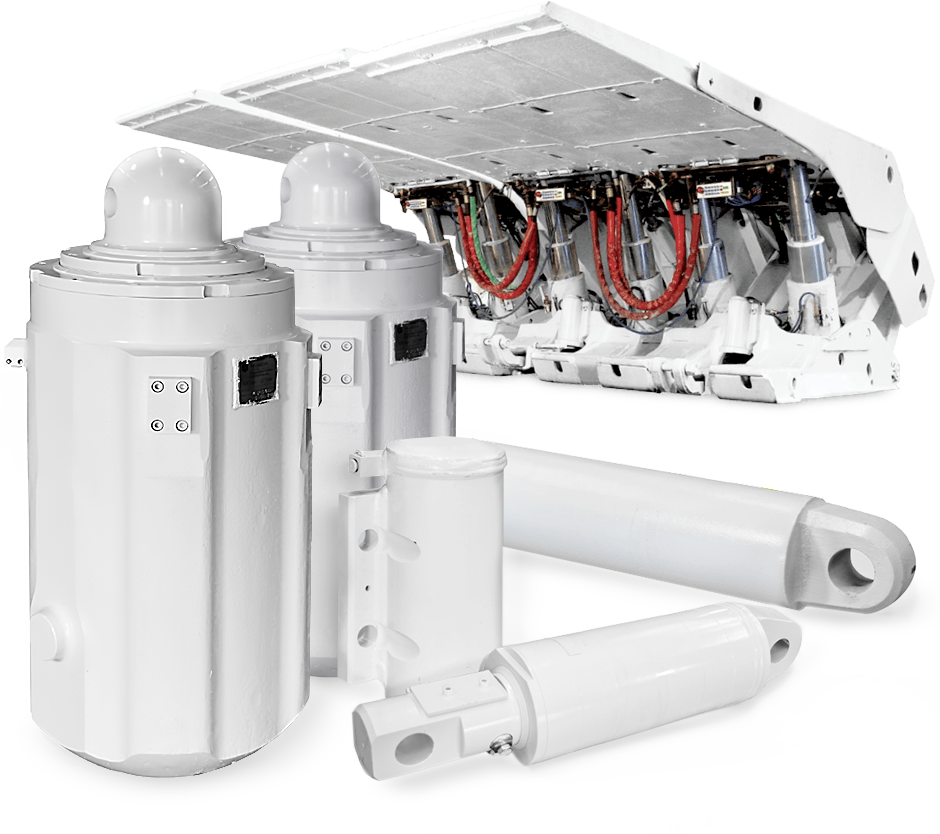

Longwall Hydraulic

Cylinder Kits

Swanson has created and manufactured our own cylinders since 1966 and leads the industry in design and manufacturing of highly-engineered hydraulic cylinders for OEMs.

Each Swanson ram, tip, base lift, and leg cylinder is designed and tested to meet–and exceed–operating specifications.

Our chrome plating and stainless cladding provides corrosion resistance and increased surface hardness for hydraulic cylinder components such as rods and tube internal diameters. Several Swanson innovations are now widely accepted as the standard practice in the longwall industry.