Industrial Chrome Plating

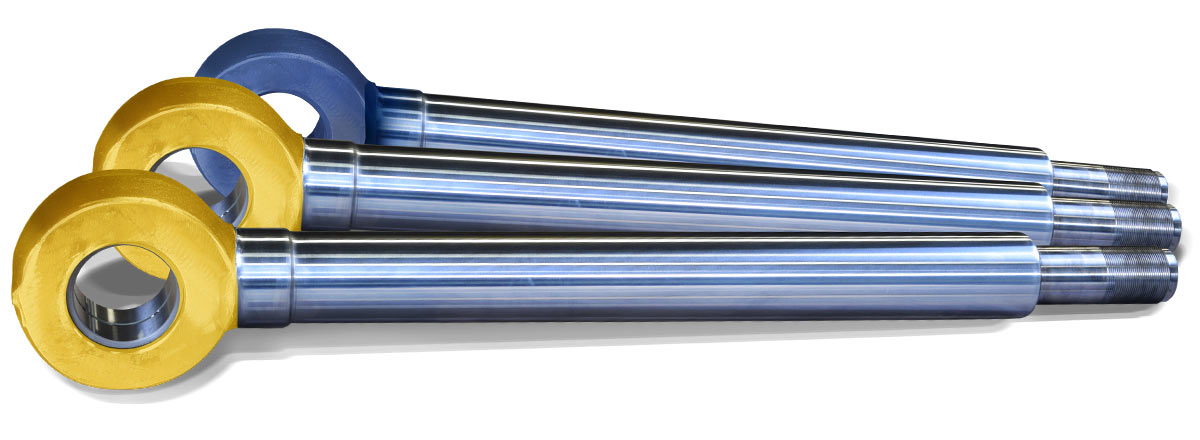

Swanson’s industrial chrome plating provides corrosion resistance and increased surface hardness for hydraulic cylinder components.

Swanson has extensive experience in the design, manufacture and utilization of industrial hard chrome for your cylinders, rods, seal fits and other components. Our ability to repair very large components with precision hard chrome makes us unique in the industry.

Whether you require precise chrome plating and polishing or heavy chrome plating of several thousands of an inch, meeting a project’s specialized needs is a hallmark of Swanson Industries.

Swanson Industries implements Industrial Chrome Plating as part of its OEM and Re-Manufacturing process. The hard chrome plating process enhances the mechanical and physical properties of cylinder components such as:

Rods | Internal Tube Diameters

Rolls and Pins

As a single-source custom manufacturing service for all types and sizes of hydraulic cylinders, Swanson designs, builds, and tests all hydraulic components to meet or exceed industry standards and exact OEM specifications. Every Swanson cylinder is backed by the best warranty support in the industry.

![]()

Cylinder capabilities ranging from two-inch to 10-inch bore diameters are produced at one of our production facilities. Swanson also offers inventory stock of cylinders that are available for immediate delivery.

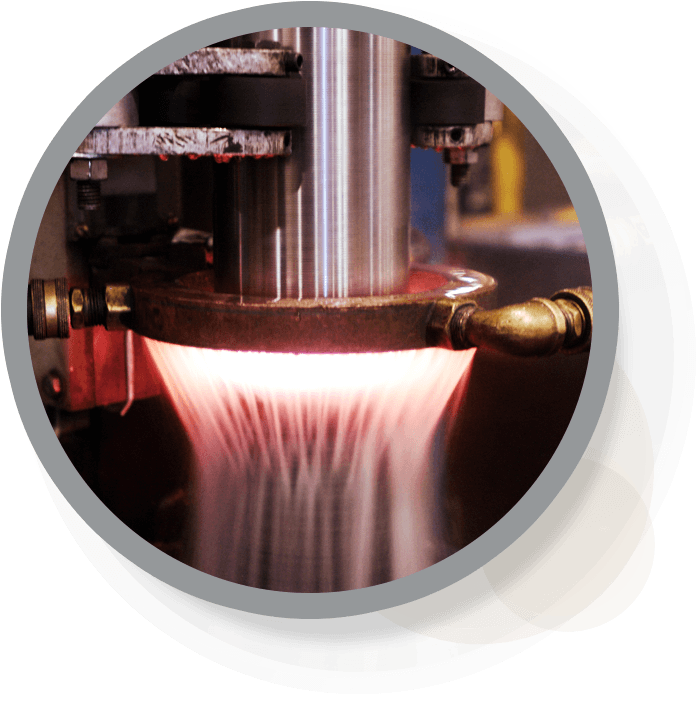

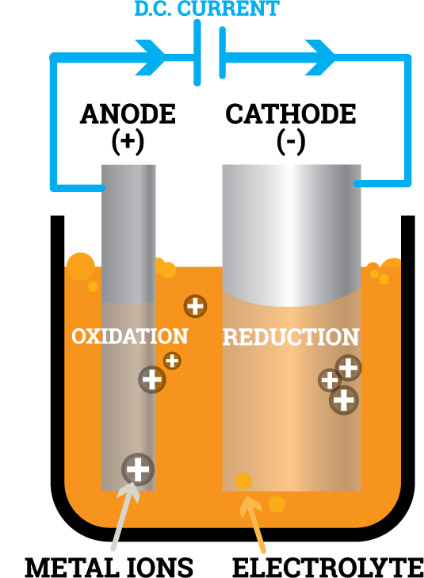

Our manufacturing process includes induction hardening for increased strength and wear resistance of hydraulic rods, rolls, and pins.

![]()

Induction Hardening

The metal part is heated by induction and then quenched. The metal undergoes a martensitic transformation, increasing the hardness of the part.

Traverse Hardening Method

In traverse hardening systems, the work piece is passed through the induction coil progressively and a following quench spray or ring is utilized. Traverse hardening is used extensively in the production of shaft type components. The component is fed through a ring type inductor which normally features a single turn. This creates a moving band of heat which, when quenched, creates the hardened surface layer.